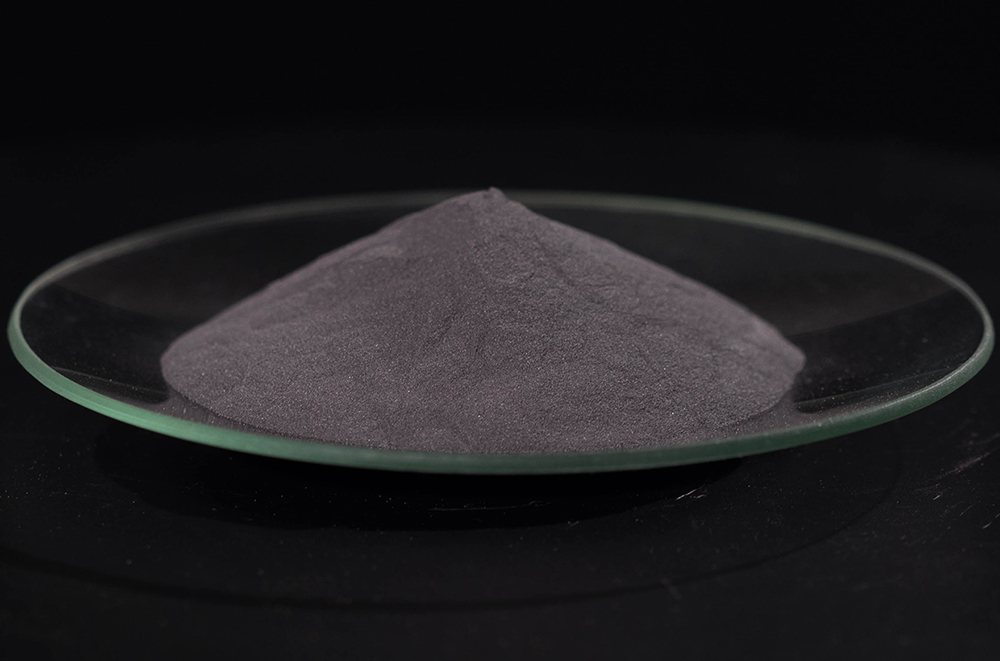

Tungsten Powder

Tungsten powder is the main raw material for processing tungsten alloy. Pure tungsten powder can be made into wire, rod, tube, plate and other processing materials and certain shape products. Tungsten powder mixed with other metal powder, can be made into all kinds of tungsten carbide, such as tungsten cobalt alloy, tungsten rhenium alloy, tungsten copper alloy and high density tungsten alloy. Another important application of tungsten powder is made of tungsten carbide powder, and preparation of cemented carbide tools, such as turning, milling, drilling and molds etc.

Grade properties

| Grade | FW-1 | FW-2 | |

| W≥99.95% | W≥99.9% | ||

| Impurities(%max) | Fe | 0.005 | 0.03 |

| Si | 0.002 | 0.005 | |

| Ca | 0.002 | 0.004 | |

| Al | 0.001 | 0.004 | |

| Mn | 0.001 | 0.002 | |

| Mg | 0.001 | 0.004 | |

| Ni | 0.003 | 0.004 | |

| Sb | 0.001 | 0.001 | |

| Cr | 0.001 | 0.004 | |

| As | 0.001 | 0.002 | |

| Pb | 0.0001 | 0.0005 | |

| Bi | 0.0001 | 0.0005 | |

| Sn | 0.0003 | 0.0005 | |

| Cu | 0.0007 | 0.001 | |

| Mo | 0.005 | 0.01 | |

| K | 0.0015 | 0.0015 | |

| Na | 0.0015 | 0.0015 | |

| S | 0.001 | 0.002 | |

| P | 0.001 | 0.004 | |

| C | 0.005 | 0.01 | |

| Type | Fsss | Scott Density | Oxygen Content |

| (um) | (g/cm3) | (%) | |

| 6 | 0.6-0.8 | 1.4-2.2 | 0.5 |

| 8 | 0.81-1.0 | 1.7-2.5 | 0.4 |

| 10 | 1.01-1.5 | 2.0-2.8 | 0.3 |

| 15 | 1.51-2.0 | 2.2-3.0 | 0.3 |

| 20 | 2.01-3.0 | 2.6-3.5 | 0.25 |

| 30 | 3.01-4.0 | 3.2-4.2 | 0.25 |

| 40 | 4.01-5.5 | 3.8-4.8 | 0.25 |

| 55 | 5.51-7.0 | 4.0-5.2 | 0.2 |

| 70 | 7.01-15.0 | 4.2-5.5 | 0.2 |

| 150 | >15.0 | 4.5-6.5 | 0.1 |

Packing: In iron drums with inside plastic bags of 100kg or 200kg net each.

Application:

FW-1 used for tungsten carbide powder, large tungsten slab or other tungsten products;

FW-2 used for tungsten contact alloys, high-density shielding materials.

Remarks:Any special requirement to the products can be discussed.