by cftungsten

Share

by cftungsten

Share

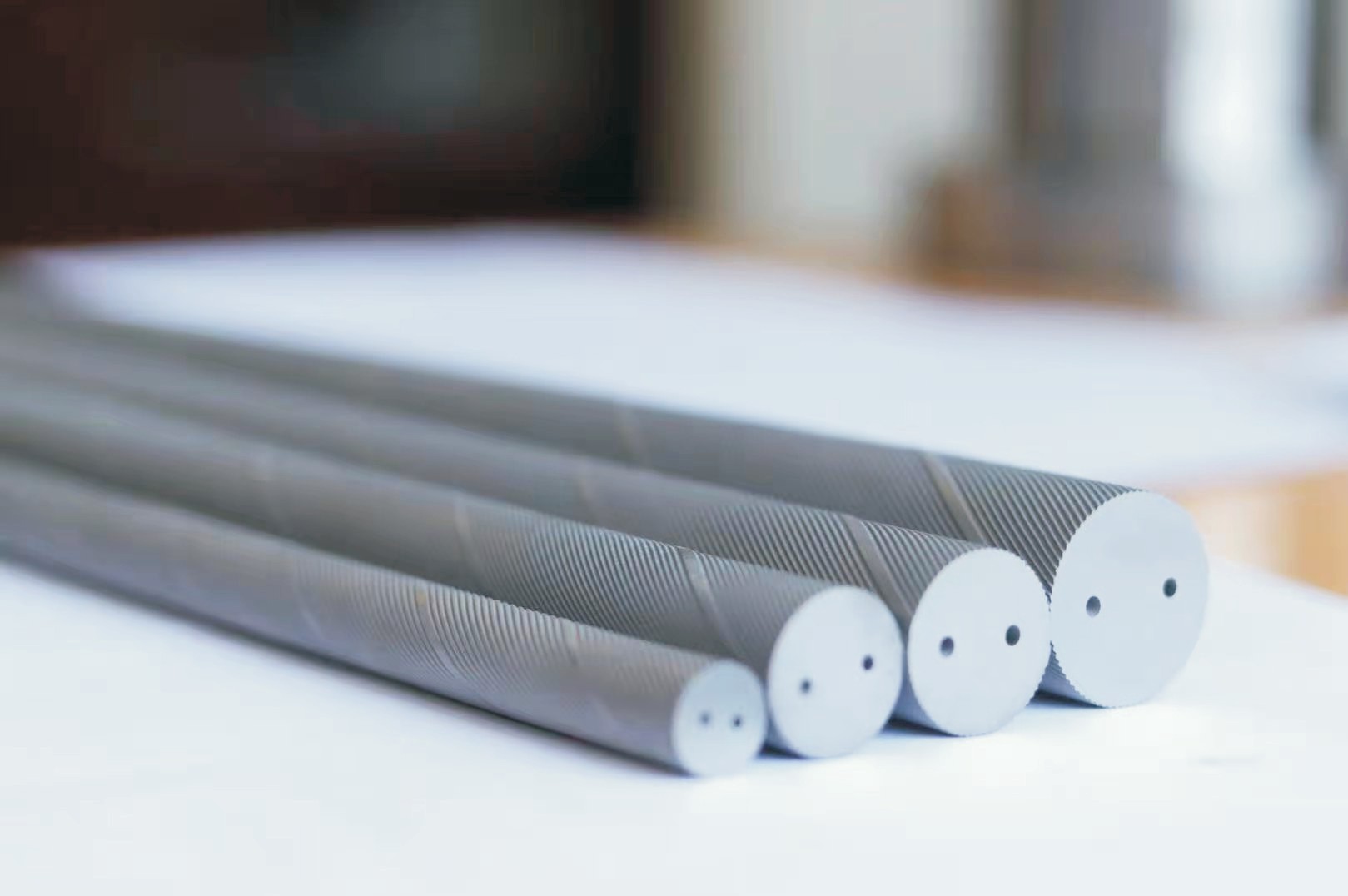

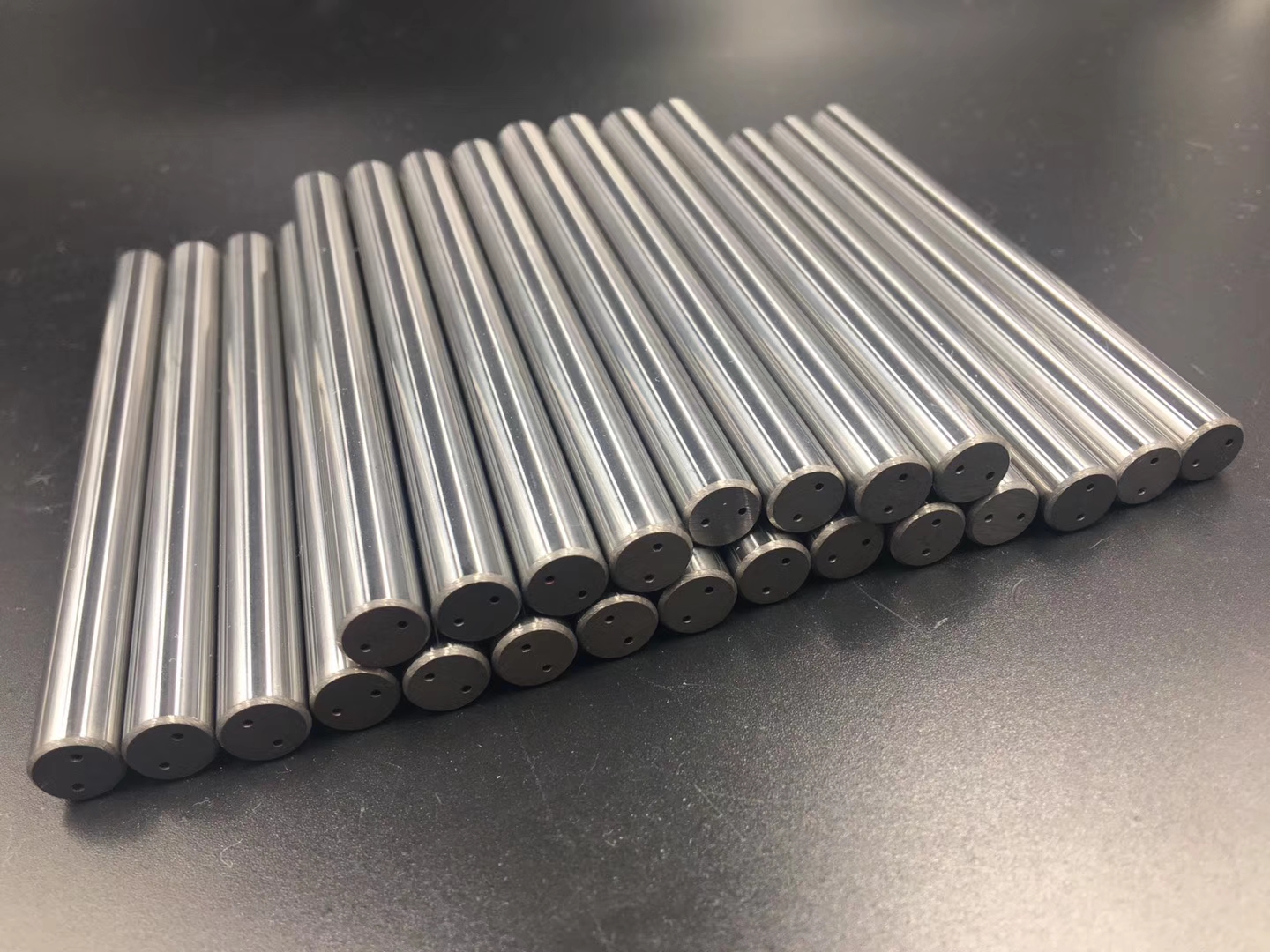

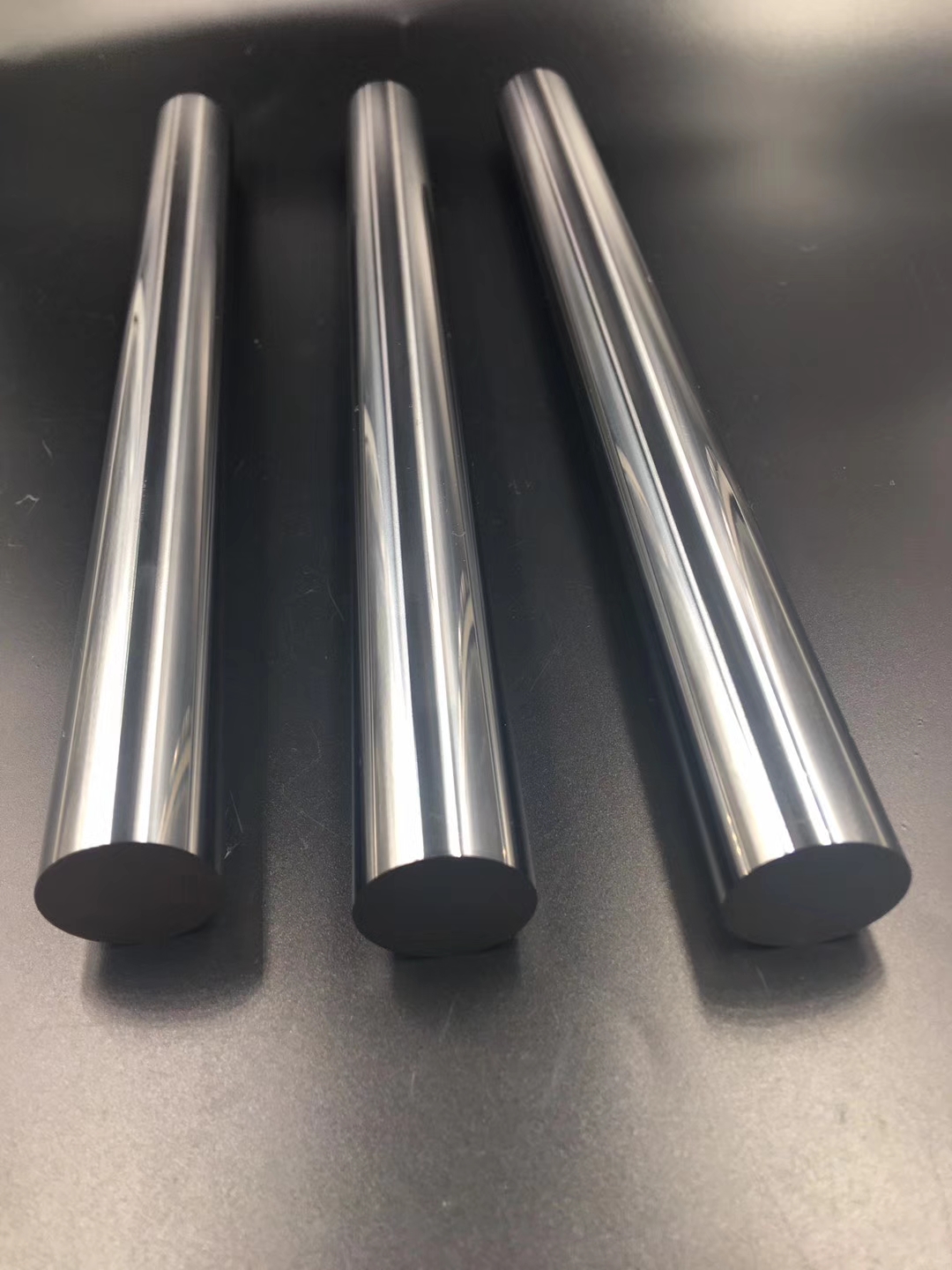

What's tungsten carbide rods

Tungsten Carbide Rod is a composite material composed of a refractory metal compound (WC:hardness phase) and a binder metal (Co:bonded phase) with different percentage produced by powder metallurgy.

How to produce tungsten carbide rods

- Wet Milling: To have the WC&Co mixture even distribution and combination and ensure uniform grain size, Tungsten carbide powder mixed with cobalt powder and other additive milling in alcohol.

- Blending pressing binder and drying: The mostly used pressing binder in the manufacture of cemented carbide, such as rubber, paraffin wax, PEG, SBS and so on. The WC&Co mixture material will dried in the process before press.

- Pressing to rods: There are two way to press with different advantages. Extrusion way, best way to press long length rods from 300-330mm. Automatic press, best way to press short rods (45-100mm length)

- Drying shaped rods: Firstly, it should be naturally dried. Second, drying in oven.

- Sintering: Sintered under 6Mpa pressuer and 1400℃+ .

- Anlysis: Inspection with hardness, TRS, Metallographic, Coercive force, density etc.

The main factors that influence quality and quality consistancy:

1. raw material tungsten carbie powder and cobalt powder, low impurities, uniform particle size distribution. recycled material contents higher impurities, its Service life will be shorter.

2. Process Craft and equipment.

Tungsten carbide rod grads and applications

Grade CF10

10%Co material with 0.8μm WC, mainly used for making drills and low speed endmill. it can maching aluminum, cast iron, 303/304 steel.

Grade CF12

12%Co material with 0.6μm WC, maily used for making high speed endmills, for maching 316A steel, Titanium alloy, aluminium alloy, nickel base alloy, acrylic.

STAY IN THE LOOP